Welcome to eReliability

eRELIABILITY was formed in 2009 by David Burnes, a well known Machinery Reliability Specialist. Previously the Director of the very successful Asset Reliability Services for 10 years and assisting many large manufacturing plants to setup, implement and benefit from their CM Systems.

eRELIABILITY recognised a need in the market place for Reliability Solutions which could transform the traditional data collecting programs into systems which could provide information to the people that require it. 20 years of PdM (Predictive Maintenance) practical industry experience and alliance with a broad range of leading PdM companies, enables eRELIABILITY to be an Industry leader in PdM maintenance solutions. Offering the latest technology and InterActive Computer Educational Tools allows eRELIABILITY to turn Maintenance Centres into Profit Centres.

Prior to founding eRELIABILITY David was the founder and Director of Asset Reliability Services for 10 years. Previous roles include Technical Services Manager for one of the World's leading PdM software and instrumentation suppliers. While at Entek IRD (Rockwell Automation) he managed the technical support and service department looking after both software and hardware systems. He has performed numerous Network System installations throughout the Asia Pacific Rim in the Power, Steel, Paper & Aluminium industries on various Network platforms & SQL database configurations. He has experience in on-site PdM consulting, PdM Training Seminars, Machine Balancing, Reliability Audits, PdM System Technical Support, Instrumentation Repair, Quality Control Systems, Failure Analysis, Surveillance & Monitor System Installations and Pro-Active Maintenance Techniques.

eRELIABILITY are industry leaders in supplying Reliability & PdM Education, Multi-Media Tools and CM Resources & Solutions to the Asia Pacific Market. Machine monitoring turn-key projects in most CM disciplines and complete plant wide solutions from equipment specifications through to supply, installation, commissioning & training are just some of the services eRELIABILITY can provide to your facility.

Vibration Analysis Surveys

With 20 Years experience in Machinery Condition Monitoring, eRELIABILITY offer a full range of Vibration Analysis Services utilising current technology 2-channel spectrum analysers.

Services include;

- Monthly plant equipment surveys, analysis and reporting

- Ad-Hoc Machine Analysis & diagnostic report

- Root-Cause Analysis

- Cross-channel Phase Analysis

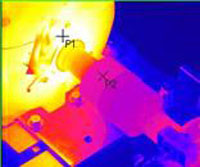

Infra-Red Thermography Surveys

- Significant investment in the latest digital technology by our partners enables us to provide the best IR image resolution and accuracy.

- Use of a compact ‘palm' size camera and 2 10mb PCMCIA memory cards ensures we monitor more equipment in one day than ever before with the greatest efficiency.

- We can provide software so that you may view your survey, trend data and resolve any spot temperatures at any time as an alternative to standard reports.

- 15 years IR experience on both mechanical and electrical (including outside HV work) equipment

Oil Tribology Services

By combining Wear Debris Analysis with other particle separation and analysis tests the results are capable of determining the Root Cause of;

- Abnormal wear commencement in drives, transmissions, hydraulics and engines

- Root cause of wear preventing wear failures in drives, transmissions, hydraulics and engines

- The component(s) that are wearing in drives, transmissions, hydraulics and engines

- Lubricant condition and suitability of running lubricants beyond their rated life

- With blowers and compressors, the efficiency and condition of main induction filters

- With combustion engines quality of combustion and efficiency of main induction filters

Laser shaft alignment

We specialise in precision laser alignments on all rotating machinery including;

- conveyor drive heads

- fans

- pumps

- cooling tower fans

- compressors

- turbines

Our technicians use only the latest Pruftechnik Rotalign Pro laser alignment equipment and quality stainless steel shims.

On-site dynamic balancing

eRELIABILITY has 20 years of on-site balancing experience and utilises current technology 2-channel analysers to perform precision on-site dynamic machine balancing on all types of machines including;

- ID Fans

- SA & FD Fans

- Cooling towers

- Blowers

- Hammer mills

New Condition Monitoring System Commissioning

Machine monitoring turn-key solutions in most Condition Monitoring (CM) disciplines, and complete plant wide solutions from equipment specifications through to

supply, installation, commissioning & training are just some of the services RELIABILITY can provide to your facility. Your site requirements are assessed and a range of application products 'fit for purpose' is specified for your site.

Applications may include:

- Vibration Analysis (fixed and portable)

- Infra-red systems

- Laser alignment systems

- Online monitoring Systems

- HV Machine Protection systems

Solutions may include:

- Capital Hardware and Software (leasing options can be arranged)

- Training solutions for all levels of your organisation

- On going Proactive Technical Support for CM disciplines

Entire turn key 'greenfields' systems can be implemented, run and managed to the 'hand over stage' where upon ongoing support is offered to your maintenance

team.

+61 498 498 600